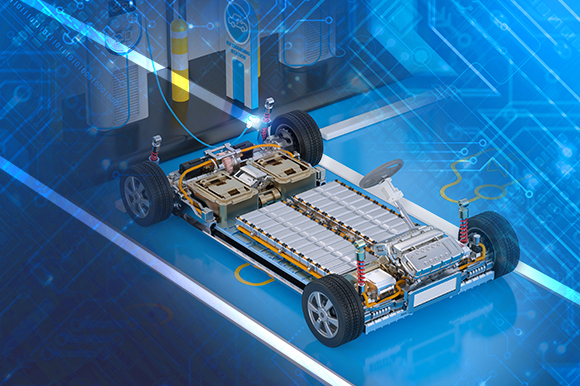

With increased volume of EVs globally, and all these primarily run by Lithium-ion batteries, the most important component in working behind these are the Battery Management System that continuously monitors each battery cell for safe operations.

As per Acumen Research and Consulting the Global Battery Management System Market Size in 2022 stood at USD 7.8 Billion and is set to reach USD 55.1 Billion by 2032, growing at a CAGR of 19.5%.

Let us dive deep and understand through this blog, about major functions of the Battery management system, key points while designing a safe and functional BMS, emerging trends, and how VVDN can help the OEMs, Automotive & Battery Manufacturers in the BMS space.

A Battery Management System (BMS) monitors individual cells within the battery pack and controls performance of the batteries. BMS is critical for ensuring the safety, reliability, and longevity of battery-powered systems in various applications such as electric vehicles, renewable energy storage, and consumer electronics.

Table of Contents

Functions of Battery Management System (BMS)

The BMS can perform several functions, including:

- State-of-Charge (SOC) Estimation: Determines the amount of charge remaining in the battery.

- Cell Balancing: Equalizes the charge level of individual cells within the battery to prevent overcharging or undercharging.

- Overvoltage/Undervoltage Protection: Prevents the battery from operating outside of its safe voltage range.

- Overcurrent/Short-Circuit Protection: Prevents excessive current flow, which can damage the battery or other components.

- Temperature Monitoring: Monitors the temperature of the battery to prevent overheating, which can damage the battery or cause a safety hazard.

- Fault Diagnosis: Detects any faults or issues with the battery and alerts the user.

- The BMS then uses the data collected to analyse charging, discharging, and balancing the battery cells to ensure optimal performance and prevent overcharging or over-discharging, which can lead to safety hazards and reduced battery life.

Emerging Trends in Battery Management Systems

Typically, the Battery Management Systems in the market today are wired that are contained within a sealed battery pack. These battery monitors are connected in a daisy chain cable with twisted-pair cabling between battery modules. With the large number of battery packs in an automotive battery, the cost of wiring and rewiring becomes so high along with the complexity. With technology advancements, companies are now moving towards new trends i.e. Wireless Battery Management Systems. These systems have advanced features over the traditional wired Battery Management System. Wireless BMS eliminates the complex sensor wire harnesses and helps in reducing cost, weight, complexity, and better communication between each battery monitor device and host MCU.

Designing Safe Battery Management System

Let’s now understand the most important steps while designing the safe BMS which are not limited to the following:

- System Architecture Design: This involves selecting the appropriate components and designing the system architecture that meets the performance requirements of the application.

- Sensor Selection and Placement: This involves selecting the appropriate sensors and determining their optimal placement to ensure accurate measurement of the battery parameters.

- Algorithm Development: This involves developing the algorithms that process the sensor data and control the charging and discharging of the battery cells.

- Hardware and Software Integration: This involves integrating the hardware and software components of the BMS and testing the system to ensure that its performance meets the requirements of the application.

- Testing and Validation: This involves testing the BMS under various operating conditions and validating its performance against the design specifications and safety standards.

VVDN Expertise in Battery Management Solutions

Designing and Development of Battery Management System (BMS) requires a multidisciplinary approach, involving expertise in Electrical Engineering, Software & Firmware Engineering, Control Systems, and Battery Chemistry. The complexity of BMS design varies depending on the application, and our power electronics team at VVDN stays up-to-date with the latest developments in Battery Technology, Safety Standards and Regulations. VVDN leveraging its vast knowledge and experience can help OEMs, Automotive tier 1 suppliers, and Battery manufacturers in designing and manufacturing BMS to meet the requirement of next-generation electric vehicles, renewable energy storage, and portable electronics.

Looking to develop a Battery Management System (BMS)? Write to us at info@vvdntech.com